Big Turbo Problem

Now the last thing

I want you to think is that it was lack of planning that

caused this problem - bigger is not

always better (even for sports car drivers!) and it wasn't sheer

greed for "more blow" here... or I could have just sought out

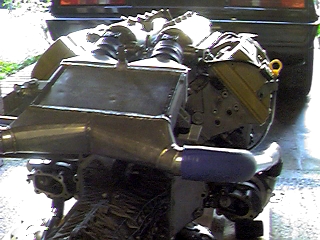

the "mother of all turbos" as in the photo here! (now that IS a

big turbo!!!)

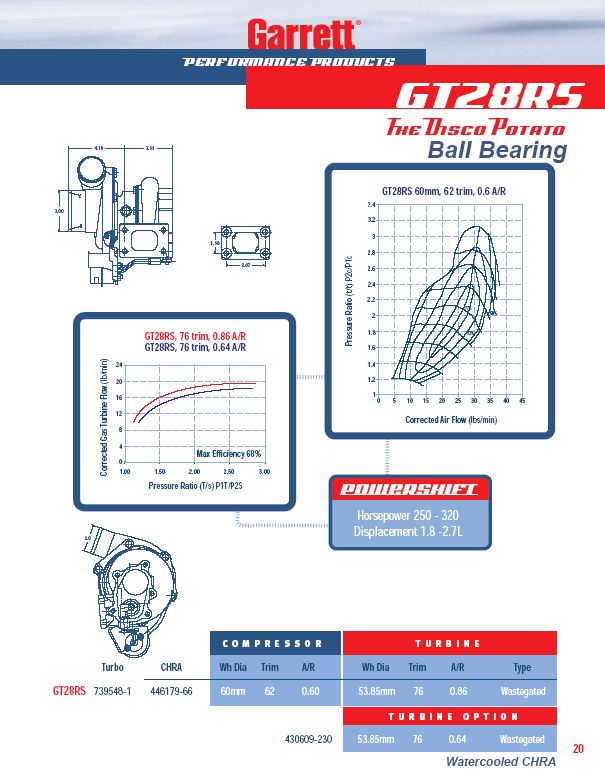

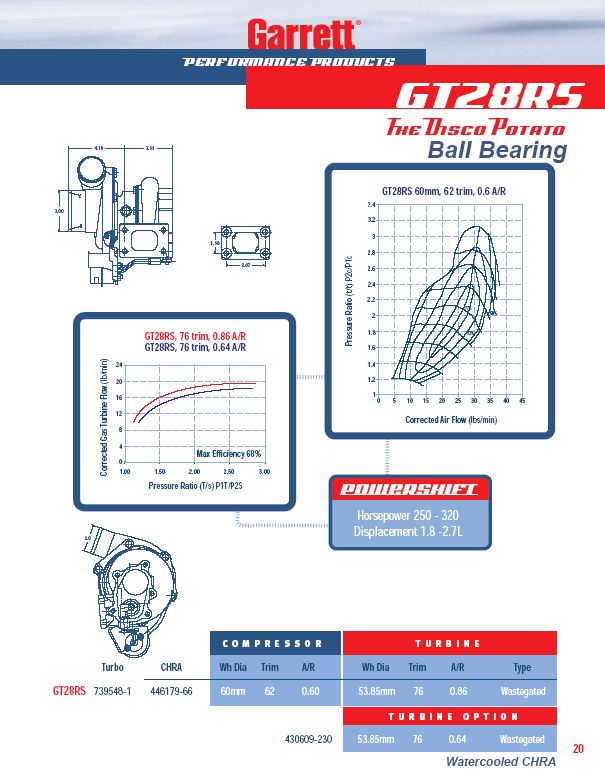

I actually spent many hours studying these parameters of the

latest and greatest ball bearing turbos, to find the perfect

match for the engine:

matching graphs (pressure Vs air flow)

- it's not just all about maximum boost, you need the turbo to

pump as much air as the engine requires for a given power output

too), trim (compressor/turbine

rotor diameter ratio) - affects turbo size, spool

time and boost/flow), A/R ratios

(housing geometry ratio for both turbine ane compressor)

- again affects turbo size, spool time and boost/flow) etc.

I also wanted the turbos to bolt straight in place

of the old T25s if at all possible, so size was always a factor

and also using a turbo with the same T25 exhaust mounting flange -

the RIGHT turbos for the engine tune level was the ultimate

concern though - I wasn't going to all the trouble of

modifying the engine to extent that I have, only to limit the

final output by the selection of turbos

The common use of "reflowed" T25s with 360 degree

bearings, or "hybrid" T28s, are really comprimises to try and

achieve more flow in the existing T25 form factor - they are never

going to supply the boost and flow plus rapid spool up that I want

So Pick the best turbos -

if they fit, all well and good - if they don't, they will be

fitted somehow, whatever it takes!

My fnal choice was the GT28RS - also known as the "Disco Potato"!

Actually this name even appears on the Garrett

product catalogue and was coined by them from the shape of the

turbo map

The Garrett GT range all have a dual ball bearing

assembly instead of floating oil bearings of older designs like

the T25 - they spool much faster and also have greatly improved

turbine/compressor aerodynamic properties

It's always difficult to get a "free lunch" though

and the more common .86 A/R turbine vesrion gives very high power

but would be some what laggy on capacities under 2.0 litres (the

3.5 litre V8 equates to 1.75 litres per bank)

More research (and cutting though sales talk!)

revealed that there is a lesser known

.64 A/R GT28RS - with this more efficient aero and ball

bearings, this should provide spool as quick as the

old T25s but hugely increased power capability

Before buying, I also emailed a few suppliers for

their views - Click here to view the

trail

On first inspection the GT28RS look impressive and definitely "man

enough for the job"

The Exhaust turbine housing, although having a very

different outlet (5 bolt exit, for a V-band adapter with larger

bore exhaust) didn't seem much larger than that of the T25s

The inlet air compressor is

much larger though - even the inlet is 3 inch, a full inch

larger than the T25s, as the photo on the right shows (GT28RS

on left T25 on right)

The alignment of the CHRA (Centre Housing Rotating

Assembly) wasn't correct for the oil banjos and coolant lines to

line up, but this can be loosened and moved without affecting the

balancing

The exhaust flange was the right pattern, but the

drilled holes were smaller than that of the T25 - this isn't too

hard to correct, so I started trying the turbos in position

and, as the photos below show, they looked magnificent.....

Take a closer look at the photos though - when I offered the

lovely new GT28RSs up to the exhaust manifolds - although I

couldn't put them on the studs because of the hole sizes, it was

clear that even if I could, the

compressor housing comes very close to the block on the near

side and the large 5 bolt exhaust exit would foul the bell

housing on the off side... OH DEAR!

Here's a photo borrowed from a recording of 5th Gear (the full

video is on the 5th Gear section)

My contact, GW, is holding up a GT28RS next to the T25 in situ -

it's obvious how close the T25 small exhuast exit comes to the

bell housing and that the GT28RS won't fit in the same

position!

Sitting there with the engine and turbos, a thought occurred to me

(probably at the same time as realising that the foolproof, but

expensive option, was repositioning the turbos completely and

fabricating completely new, one off, manifolds) that more

clearance could be afforded by spacing the exhaust manifolds out

at their natural 45 degree angle (moving the turbos downwards and

outwards)

It was time to share these findings with the PM71 project team

- Click here to read

the email trail

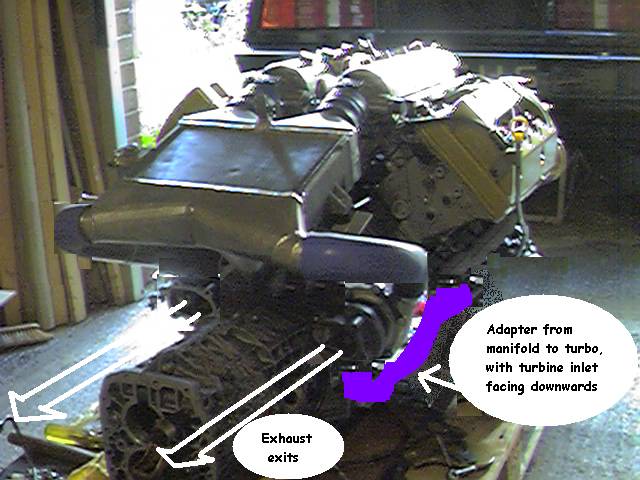

I made up the annotated pictures below to explain the

situation and how a manifold spacer could possibly be used

In a positive vane, I also took these photos with the turbos in

the positions they would adopt with manifold spacers - they just

might just be propped up on mallets, but they do give a good

impression of how it would look

They certainly look a significant upgrade to T25s and clearly

what's needed to match the rest of the modofications to the

induction... I know I'm doing the right thing insisting on

getting them fitted!

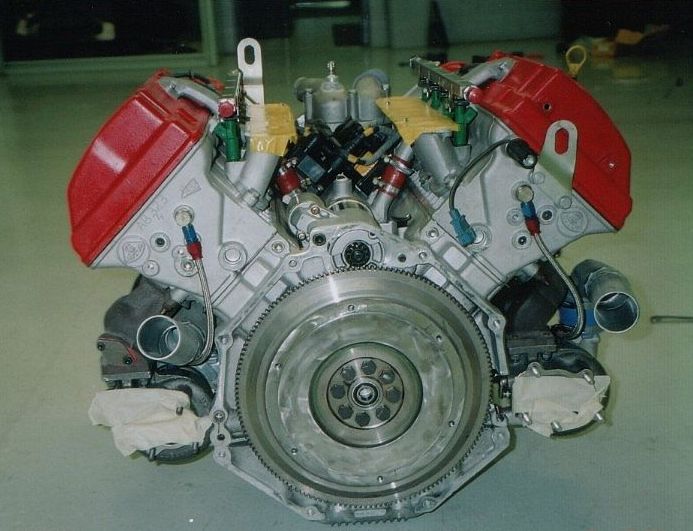

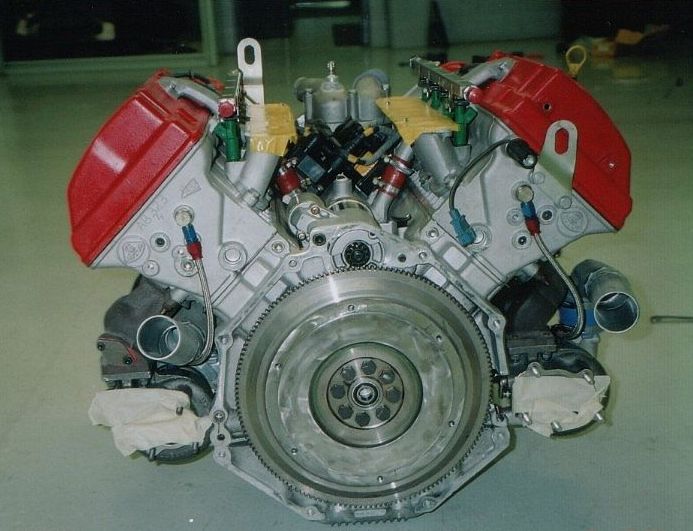

Now, whilst I was surfing the Net, I happned across a post about

an Esprit V8 being prepared by Garrett

themselves for a racing series in the USA

It was clear from the photos that, as you might expect of

Garrett, they were changing the turbo installation - the shot on

the right shows the engine in the workshop, with modified plumbing

for connection to their chargecooler (photo

in "Engine" section of "Design" section)

This shot shows the car with an engine on stand at an exhibition

- but click for the enlargement and look closely at both turbos...

the one on the right has the old 3 bolt exhaust exit (probablt

a T25), but the one on the left has a new 5 bolt exit!

I emailed the message board, got the Garrett and race teams

contact info and emailed them to find out what was going on - Click here to read the email trail

So the answer was that they were using GT25R turbos (that

have the 5 bolt exit but are not as large as the GT28RS) - the

photo on the right shows how the team have cut a slot in the bell

housing to fit the right hand GT25R.

The dimensions of my GT28RSs look like they make

even drastic measures like this, less than what is needed - they

need to be spaced away from the engine/transmission

However, this means that they encroach on the

chassis tube that runs very close to the outer side of the turbo

The annotated picture from beneath the car illustrates the

problem here - without the engine being fitted to the chassis, it

is very difficult to gauge how much room I have to play with here

I may, of course, have to fit the engine in order to find the

optimum position for the turbos and the exhaust manifold

arrangement

This isn't a step I planned on doing though - I'd rather

find a way to keep to my plan of developing the complete

engine/induction, map the ECU at the dyno/engine cell and then

start the assembly

You'll notice from the underside view that the exhasts have to

take a fairly sharp vertical "dog-leg" over the drive shafts too.

So moving the turbos rearwards would exacerbate this problem.

If I do completely reposition, I'll probably use the

position shown on the right here - this will allow straight

exhaust exits to the rear of the car, won't present oil drain

issues and provides an even shorter inlet to the chargecooler

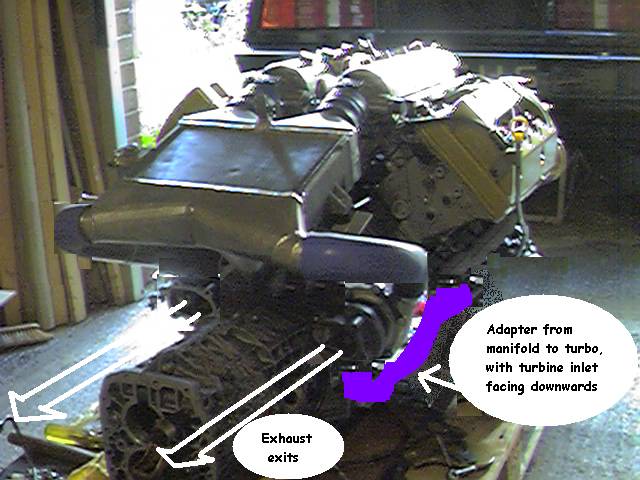

The diagram shows a cheaper alternative of using an adapter pipe

from the standard manifolds - but this position could also be

used with fabricated stainless steel manifolds

Either way I'm concerned about the length of the pipework to

the turbines - exhaust manifold design is quite complex

because of the way the pressure pulses from each cylinder combine

- this is important on normally aspirated engines to provide an

"extractor" effect but it is key on turbocharged engines to ensure

spooling of the turbine

The odd and even cylinders are combined in the primaries and the

two bores are kept seperate right up to the turbo inlet on the

standard manifolds) - the thing to avoid is what's called pulse

reversion - where the exhaust gas travles in the wrong

direction! It is possible to merge the primaries at a

"collector" point and then run a secondary pipe to the turbo, but

distances/dimensions are important....

Well that's the

Big Turbo Problem defined - what the solution is, I'm not

absolutely sure yet!

Oct 2011:

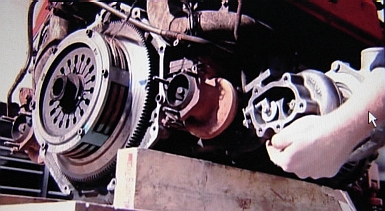

I am definitely having stainless steel manifolds fabricated

now - after a chat over lunch during a track day at Brands Hatch,

the ideal company has come to light...

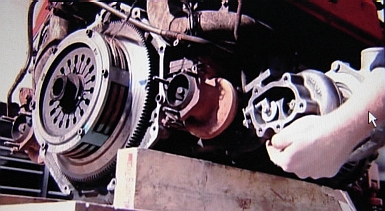

Here's one the GT28RS turbos propped up on the clutch (which will

probably also need an upgrade for high power/torque) showing the

approximate position where the new manifold should meet it